How to Create a Culture of Sustainability in the Workplace

The need for a shift towards more sustainable and responsible practices in China is undeniable. Sustainability is no longer a secondary consideration, but an integral part of the long-term viability of businesses and their industries.

By: Alizée Buysschaert (Zero Waste Shanghai)

Editor: Dorcas Wong

Many companies incorporate socioenvironmental practices as an ‘add-on’ to their current way of working. However, this will usually have a limited impact on the company culture, supply chain, or day-today life at the office. Thus, the focus can sometimes be disproportionately placed on how to improve the environmental, social, or economic circumstances external to the company, rather than looking at how to ensure the company’s system are maintained over time.

In reality, the practices you adopt within your workplace will have a big impact on how far you can go with adopting socioenvironmental practices within your business more broadly. The process of creating a sustainable company starts with an internal dialogue, training, and effective management before it moves to an external one with company stakeholders (clients, community, suppliers, etc.).

Moving from recycling to circular practices

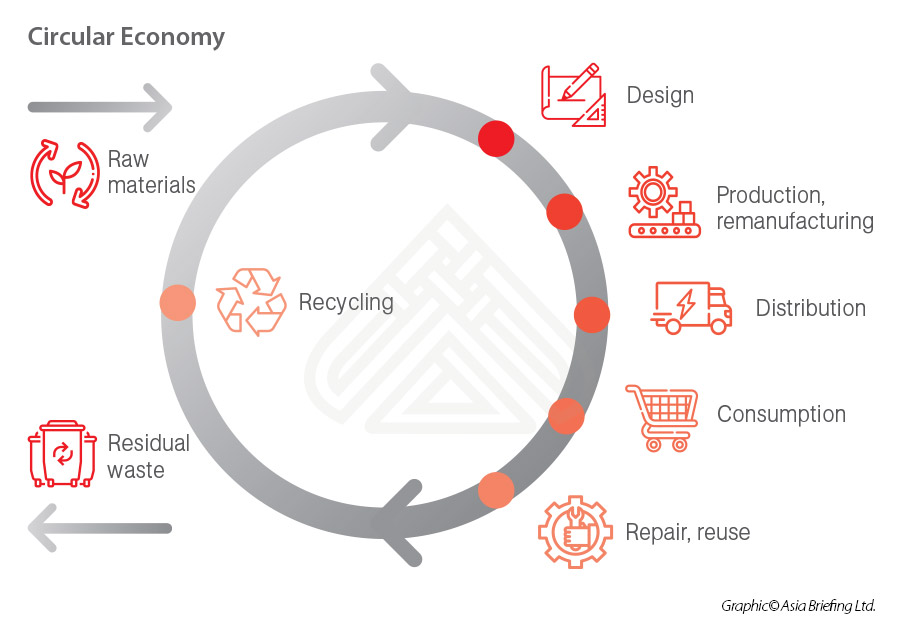

When considering sustainability, many corporations jump immediately to recycling. Understandably, this is what has been commonly associated with sustainability for many decades. Shifting the focus to a ‘circular’ mindset, however, allows a company to go a step further and cut down on its waste.

While recycling is about converting waste material into new usable objects, a circular economy encourages the reuse and repurposing of an object (as seen in the diagram below). This enables companies to extract maximum value out of each item.

Through circular practices, a business is naturally streamlined through the removal of product inefficiencies and, in some cases, the creation of new revenue streams from previous ‘waste’ materials.

The starting point of this new economy is to design the product in such a way that by the end of its lifecycle, the materials are easy to disassemble and reintroduce into the supply chain. This not only reduces the environmental impact, but also allows companies to retrieve the materials back from their customers, making them less reliant on purchasing new raw materials prone to price fluctuations.

Developing sustainable practices within the workplace

Sustainable practices require a strategy, just like other departments of the company, but this is often overlooked. Here, we provide a priority list of what to look out for when developing sustainability in the workplace.

1. Waste audit

Looking where it hurts: the trash bin. A waste audit is a process that can be used to determine the amount and types of waste that are generated inside an organization. It can help an organization to identify where materials come from by individual items and allow it to determine how they can reduce the amount of waste that they generate, save money, and implement a healthier policy.

2. Redesign

Once the wasted materials have been identified, the redesign process can be initiated. This step is frequently the most overlooked because it is often the most difficult. It involves analyzing the products and looking at where materials can be saved, easily disassembled, and re-integrated into the supply chain. It is also the most impactful and important step.

3. Reduce

Reducing refers to reducing the materials used for both the product and the packaging it comes in. Though reductions may appear small, they can have impactful cumulative effects. For example, a case study conducted by Green Business Certification showed that reducing the thickness of cardboard packaging can result in exponential savings over time.

The process of reducing also goes through the purchasing department, such as by realigning to purchase from greener and more sustainable sources.

4. Reuse and repurpose

Reusing and repurposing materials is a creative process and one of the most profitable as well. This is where materials are reintegrated into the supply chain and can therefore dramatically reduce costs on raw material acquirement and production.

At this stage, we suggest that our clients seek collaboration with partners or stakeholders from industries that could benefit from the wasted materials. It often allows for a win-win situation where one company sells the wasted material (creation of a new revenue stream) and the other company receives the raw materials at a more attractive price and can count on a reliable source.

5. Recycle

As mentioned before, recycling used to be the go-to solution for companies who aspire to be sustainable. However, recycling alone is not the solution to the problem – it is merely buying time before the final product ends up in a landfill or incineration. Besides, recycling is an intensive process that requires a great amount of energy, water, and sometimes harmful chemicals.

Recycling in the circular economy can be done in two ways: upcycling and downcycling.

- Upcycling is the transformation of an existing material or product into a completely new one through mending, forging, sewing, and other means (for example, turning a wooden door into a table).

- Downcycling is the process of reducing a material back into its original state and recreating a new product from the raw material (for example, melting plastic back into pallets to create new products, or turning clothes back into yarn to use for car seat stuffing or housing insulation).

6. Rot

Last but not least, and probably the most valuable of all, is to turn food back into soil. A big part of the climate crisis we find ourselves in today is because our soil is unhealthy and inorganic. They do not contain as many life forms as before and therefore agricultural workers are pressured into using fertilizers.

In large cities around China, 30-35 percent of daily waste consists of food, so one would think that creating compost would not be a problem.

That being said, in practice, food and green cuttings are not separated from the other waste streams and find themselves in landfills, which do not allow for biodegrading, or in incineration chimneys, which require more energy to burn food waste than plastic or cardboard.

Driving a culture of sustainability through effective leadership

Sustainability leadership is key if a company aims to be part of this new economic and social transition. Managers may put their employees through outdoor team-building activities or environmental documentaries, but if leadership is not actively involved in creating a culture of sustainability, the buzz created around the topic will be short-lived. Sustainability is a vast topic and can be understood through different perspectives and opinions. It’s important to start the journey towards circularity by asking “what does sustainability mean to you as a company?’”

This first step is crucial before defining the company’s new sustainability goal. When the team is aligned on what this new economic model entails, and how important it is for the long-term viability of the company, we are able to define a goal and a roadmap that will lead the company on its way to a more profitable and eco-friendly way of working.

A version of this article appeared in the December 2019 edition of our China Briefing Magazine, titled “Corporate Sustainability in China”, produced in partnership with Zero Waste Shanghai. The magazine is available as a free download on the Asia Briefing Publication Store.

About Us

China Briefing is written and produced by Dezan Shira & Associates. The practice assists foreign investors into China and has done so since 1992 through offices in Beijing, Tianjin, Dalian, Qingdao, Shanghai, Hangzhou, Ningbo, Suzhou, Guangzhou, Dongguan, Zhongshan, Shenzhen, and Hong Kong. Please contact the firm for assistance in China at china@dezshira.com.

We also maintain offices assisting foreign investors in Vietnam, Indonesia, Singapore, The Philippines, Malaysia, Thailand, United States, and Italy, in addition to our practices in India and Russia and our trade research facilities along the Belt & Road Initiative.

- Previous Article What does the Yangtze River Delta Integration Mean for Businesses in China?

- Next Article Trade Secrets’ Protection in China: What is Changing?